Waste Management

Waste Management

Industry Challenges in Waste Management AI

- Diverse waste material types across residential, commercial & industrial sources

- Need for automated, scalable waste segregation

- Constantly changing waste streams influenced by human behavior & seasons

- Overlapping or contaminated waste materials requiring detailed classification

- Variability in lighting, background, and container environments

- Requirements for hazard, chemical, and biomedical material detection

How rProcess Supports the Waste Management Ecosystem

rProcess provides high‑precision annotations that help AI systems identify and segregate materials, detect hazards, and guide automated waste‑sorting equipment.

Annotation Services for Waste Management

- Waste object detection & classification

- Segmentation of recyclable vs. non‑recyclable materials

- Contamination identification (liquids, food waste, mixed materials)

- Hazard & chemical material tagging

- Temporal tracking for conveyor‑belt video feeds

- Labeling for autonomous sorting robots

Why Choose rProcess?

Expertise in Complex Waste Material Classification

We accurately classify diverse waste types, from recyclables to hazardous materials, across varied environments.

High Accuracy Across Plastic, Paper, Metal, Organic & E‑Waste

Our teams provide consistent labeling for highly variable and mixed waste streams.

Scalable Pipelines for Municipal & Industrial Recycling

We support large waste-management organizations with continuous, high-volume annotation.

Advanced QC for Production‑Grade Recycling AI Models

Our quality workflows ensure reliable datasets for sorting systems, contamination detection, and robotics.

Waste Management Case Studies

rProcess partnered with a leading AI and robotics company to revolutionize recycling economics. The project focused on creating high-quality annotated datasets to train machine vision models for automated waste segregation in Municipal Solid Waste (MSW), Construction & Demolition (C&D), E-Waste, and battery recycling.

- Developed a large dataset with precise segmentation and labeling of waste objects

- Applied AI, computer vision, and smart sorting system workflows

- Delivered facility-wide data insights for material purity, performance, and waste characterization

- Supported design of robotics systems for targeted segregation of high-value commodities

- Enabled the creation of machine learning models for accurate waste classification

- Annotated 350 diverse datasets from industries such as manufacturing, C&D, electronics waste, and MSW

- Supported automated robotics for safe, efficient, and precise segregation

- Improved recovery of recyclable materials, reducing landfill dependency

- Provided scalable annotation workflows for multiple waste domains

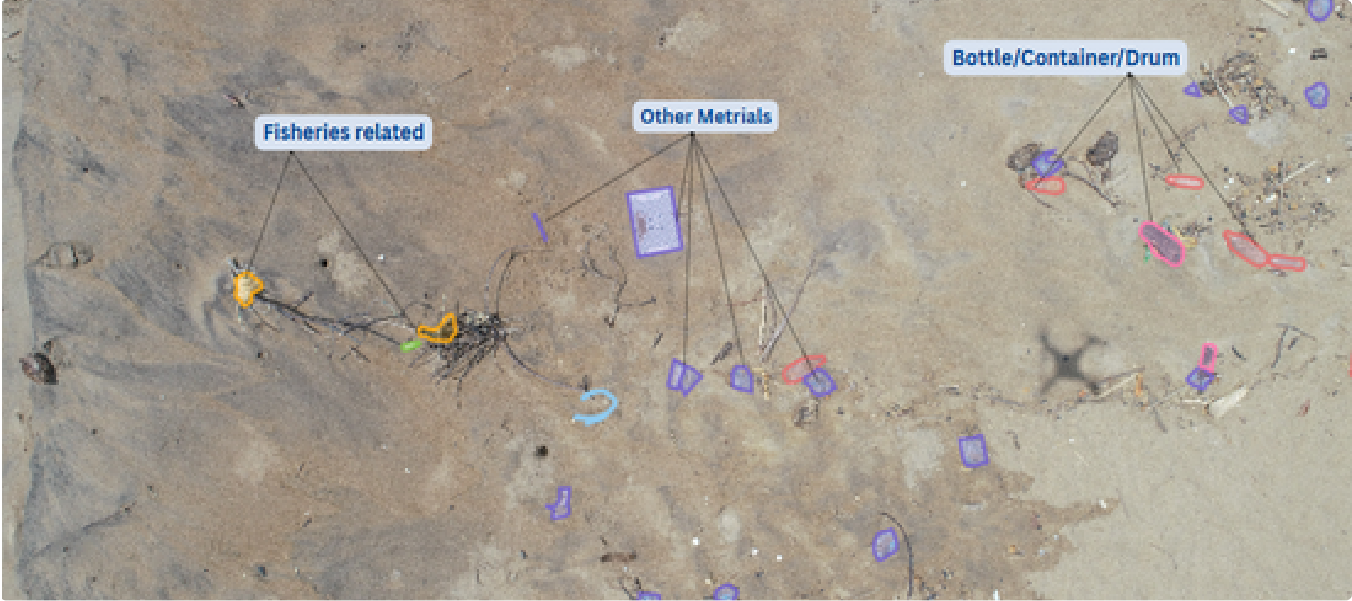

Marine pollution monitoring was hindered by inconsistent and low-detail classification methods. Litter items on beaches varied in size, shape, and visibility, while traditional categories (plastic, glass, metal) lacked the granularity needed for targeted interventions. Low-resolution drone imagery further complicated accurate identification.

- Classified beach litter into 100+ detailed categories for better accuracy

- Applied quality checks to detect and correct errors

- Established standardized annotation guidelines for consistency

- Designed a scalable framework to support large-scale marine monitoring

- 90,000+ images precisely annotated

- High-quality dataset created for machine learning applications

- Reduced misclassification through clear guidelines and exclusions

- Annotated waste images into 100+ standardized material categories

- Applied consistent labeling rules to distinguish similar materials (e.g., PET clear vs PET green)

- Conducted quality control reviews to ensure accuracy before dataset delivery

- Delivered 45M+ precise segmentations and 3M+ verified classifications

- Reduced misclassification with clear, detailed category definitions

- Improved recycling efficiency through accurate material recognition

Public and commercial spaces struggle with waste mis-sorting, leading to contamination and lower recycling efficiency. Traditional bins do not actively engage users, making it difficult to improve sorting habits. Additionally, fixed pickup schedules often result in unnecessary collections, raising operational costs.

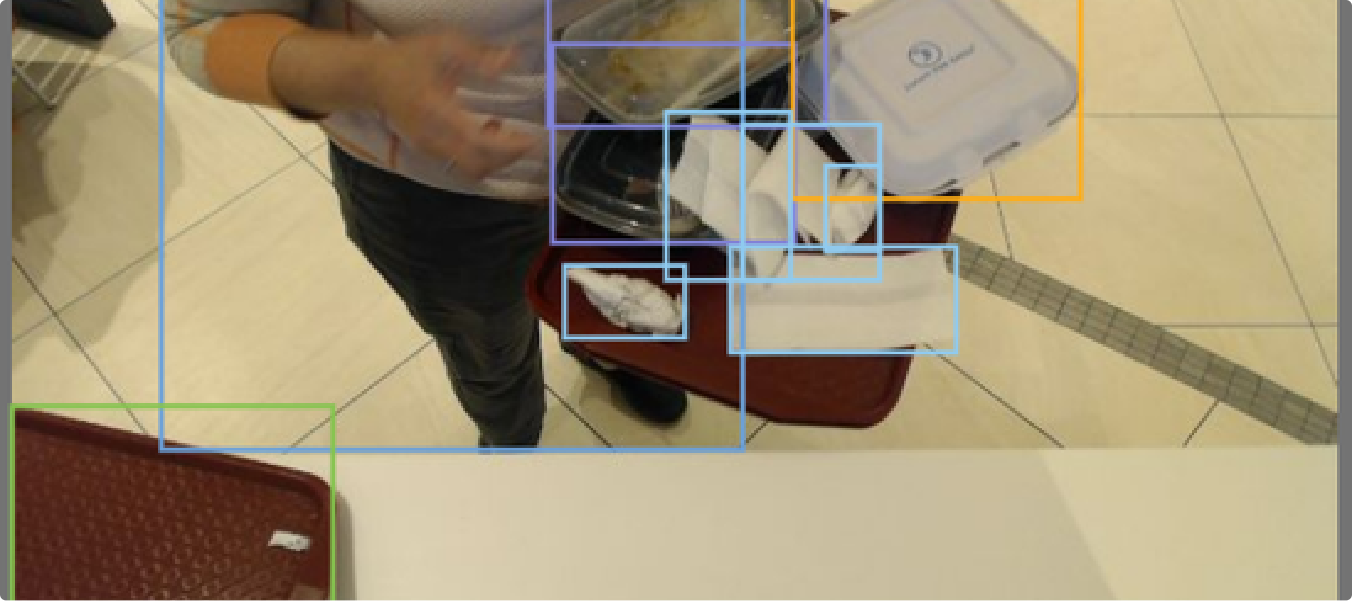

- Annotated waste images directly from disposal points to train the AI system

- Labeled items across multiple waste categories to enable accurate real-time disposal guidance

- Applied quality checks to ensure consistent and reliable AI classifications

- Delivered 4.0M+ annotations and 700K+ accurate classifications

- Built a high-quality dataset to power AI waste recognition

- Reduced contamination through improved recognition accuracy

- Enabled real-time user feedback at disposal points, driving better sorting habits